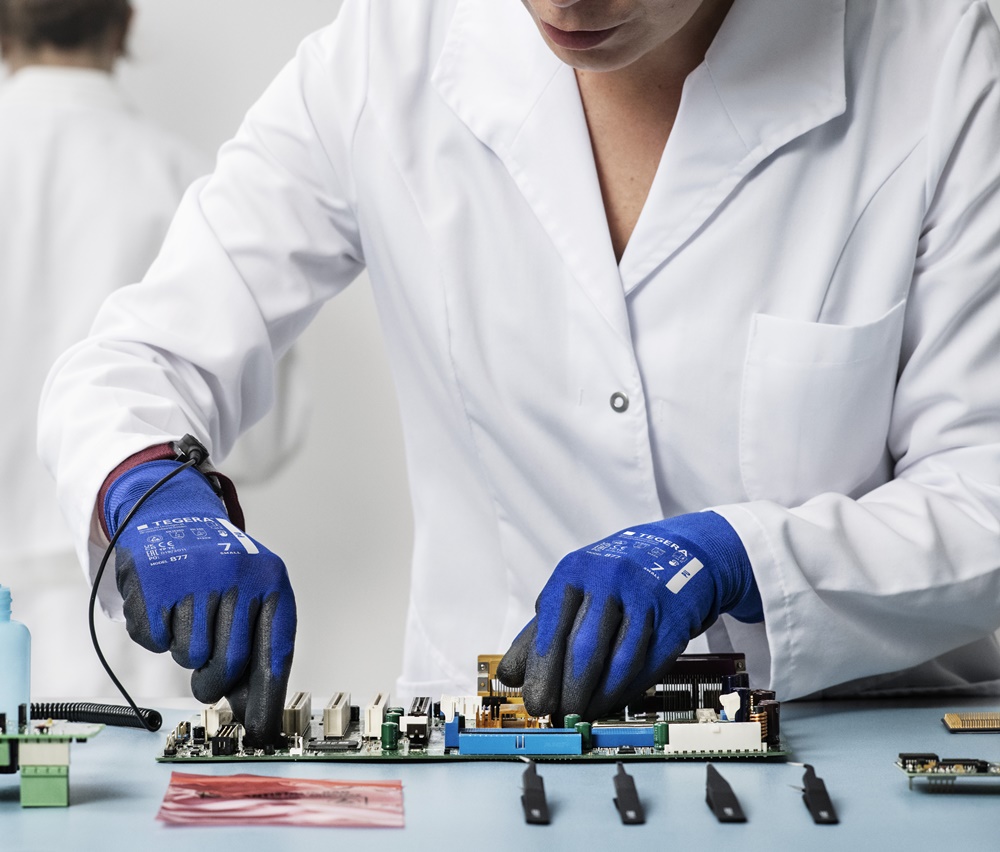

ESD Gloves protects your electronics

More and more products and production equipment contain electronics and ESD sensitivity is increasing. It is impossible to avoid static electricity completely, but a large part of the risk can be minimized with ESD or ATEX certified work gloves.

EVEN THE WEAKEST SPARKS CREATED BY YOUR EMPLOYEES CAN KILL YOUR ELECTRONICS.

THIS IS HOW TO PROTECT THEM BOTH.

We all live in the electronic age. That is why we now need to increase safety in production environments. Since more and more products and production equipment contain electronics, ESD sensitivity is increasing. This has an impact on both productivity and reliability. An increasing number of manufacturing industries need to improve their use of ESD certified protection to minimize costs of defective product components and damaged electronic equipment.

The negative effects of static electricity in the workplace are electrostatic discharge (ESD) in and around sensitive electronic equipment and explosions due to static discharge (ATEX).

The best way to solve the problem of static electricity is to make sure it never happens in the first place. It is impossible to avoid static electricity completely, but a large part of the risk can be minimized with ESD or ATEX certified work gloves.

ESD work gloves for protecting equipment. ATEX safety gloves for protecting humans.

Electrostatic charge requires two different types of protection. One protects electronics from being damaged by human discharges. The other protects humans from being injured in explosive environments where static discharges can trigger explosions.

In the first scenario, ESD certified gloves offer protection.

In the other, you need ATEX gloves.

In industries where static charge is a problem, gloves with conductive properties are important. These gloves are dissipative, which means they allow electric charges to flow in a controlled manner. You need a complete system, which also includes, for example, shoes and flooring to provide ground connection potential.

Low voltage can do great damage.

You have probably experienced static electricity yourself after stroking a cat or rushing forward on a carpet. Static electricity is not dangerous to humans. We can withstand several thousand volts with a low current, but electronics can be damaged by as little as 10 to 100 volts. That is why it is important to test ESD protection products to ensure they work even for such low voltages.

“It is very important that ESD gloves are tested so that their electrostatic potential isn’t too high”, says Karin Rundqvist, a laboratory engineer at Ejendals and a specialist in personal protective equipment for ESD in particular. “ESD certification has to check that the build-up of electrostatic charge does not exceed 100 volts. Unfortunately, not all suppliers are testing for this.”

Why do we need so many different gloves? Because electronics are everywhere.

Why do we need so many different work gloves with ESD protection? Because there are now so many different jobs where there are electronic components that need to be protected. Regardless of what tasks your employees carry out in an ESD-sensitive work environment, there should be a glove that protects them regardless of your budget. Different work gloves have different characteristics for different tasks.

Equip your employees with the best protective gear.

You can’t always control your working environment and the conditions, but you can equip yourself with the very best protective gear to prevent accidents and injuries. To ensure that safety gloves do what they promise, make sure that they are rigorously tested.

ESD and ATEX protective gloves

TEGERA® presents one of the markets widest ranges of ESD and ATEX protective gloves.

Go to glovesESD - Electrostatic discharge

Electronics can be damaged by a discharge of very low voltage.

Want to learn more?