TEGERA's Guide to Cut Protection Gloves

Crafting cut protection safety gloves that are comfortable and fit well, while safeguarding hands from sharp edges and knife blades, is a challenge. We've dedicated years to developing and refining materials for excellent cut protection, ensuring our cut protection work gloves are flexible, extremely thin, and comfortable to wear

- We have adapted to meet the tough demands on production capacity of modern industry.

- We are working to achieve the best possible results in terms of fine motor ability and grip.

CHOOSE THE RIGHT CUT RESISTANCE LEVEL

We offer a wide range of cut protection gloves in each level of protection.

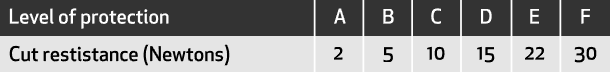

CUT PROTECTION GLOVES ARE GRADED ON A SCALE FROM A TO F IN EN 388:2016

The gloves are graded according to the test method TDM (ISO 13997)

- Cut level B: For handling small and sharp objects, resists at least 5 Newtons

- Cut level C: For extra protection against sharp objects, resists at least 10 Newtons

- Cut level D - F: high protection level, for handling sharp and heavy objects

- Cut level D resists at least 15 Newtons

- Cut level E resists at least 22 Newtons

- Cut level F resists at least 30 Newtons